What is a Factory Audit?

Identifying the right factory determines the future of your products, because the capabilities and capacity of your manufacturer have to align with your needs and expectations.

We have discussed some tips about choosing the right supplier before, in this article we will describe the process of the factory audit, a top method of supplier capability assessment.

Why use a Factory Audit?

Let’s imagine that you are sourcing products and have a potential supplier in mind. What can help you to be certain that you are making the right choice choosing it? A personal visit for an overlook of the factory production line, capacities and capabilities definitely would give you more perspective on the supplier, and be more influential in your decision. When you cannot do it yourself, a factory audit service by a recognized inspection company would come in handy.

As well, if you already cooperate with someone and would like to improve their overall performance, a detailed CAP (corrective action plan) with improvement suggestions for the facility would be issued after the factory audit, following which the factory can get on the right path for the improvement of their quality system.

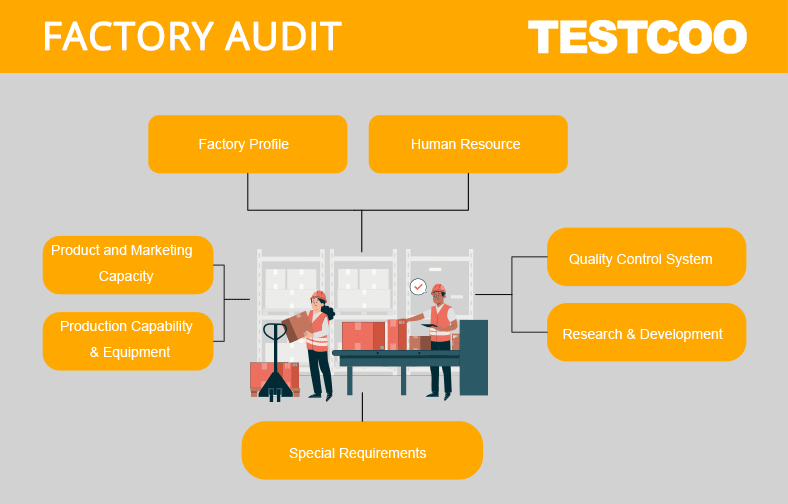

7 Key Elements to Assess When Conducting a Factory Audit

Generally, during the factory audit we will focus on the following aspects:

Factory profile

Human resource

Foreign trade capacity

Production capability

Quality control system

R&D

Special Requirements from Client

1. Factory profile

First of all, we need to make sure whether your supplier is legit and has valid documentation.

At this stage the auditor would check that your required products are within the factory’s registered business scope, and whether the factory/supplier has validity to manufacture and export the required goods.

Is the company a manufacturer or a trading company, are their actual address and facility size the same as the registered ones? What is the year of their establishment and registered capital? These are the basic questions you will receive an answer to.

Usually the auditor would check the business license, export license, ISO 9001 and other ISO accreditations, BSCI / Sedex SMETA report, or specific documentation needed based on the supplier’s business scope.

2. Human resource

Have you ever wondered whether the person you are in contact with is a real employee of the company you want to partner with? An audit can help to bring more light to your potential supplier’s human resources.

It would allow you not only to check whether your contact is really an employee of the company, but also to understand how many shareholders, senior managers, and engineers the company has: internal quality control inspectors, R&D engineers, and their working experience in the company. A company with a bigger number of QC-related experienced staff is paying more attention to the quality control.

3. Product and marketing capacity

The geographical focus of the factory’s exports can tell a lot about products’ quality.

If the factory produces mostly products for export to Western Europe, it would have higher quality expectations for the products, than, let’s say, the factory that produces to Africa.

In addition, the factories that export to Europe would have more experience and knowledge about European standards, and compliance to them.

But that isn’t all, the factory audit can help to bring more light to the supplier’s business volume overview for the specific regions, as well as get the statistical data of the supplier’s annual turnover and export turnover, get other customer’s referrals and check that this factory already has a representative in your country.

4. Production capability & equipment

This is the main engine of the factory, thus we check it closely to ensure that it is well functioning. At first, the auditor will verify whether all necessary parts of the production line are present – from the raw material input, to the product packaging stage.

Why is it so crucial? It is quite common that small and middle-size manufacturing facilities don’t have all the necessary production equipment, thus it means that at some stage the production would be outsourced to another manufacturer. With product movements from one facility to another comes problems – the products can be damaged on the way, or the production would be less controlled and more problems can occur at the outsourced manufacturing facility, when your partner has no power to pull the strings.

Besides the facilities verifications, the auditor will check production machinery status – whether it is in use, repaired, or maybe out of use and too old, just collecting dust particles in the factory.

5. Quality Control system

The factory should have an established and well operated internal quality control system – to track and improve quality issues of the production internally. What if they don’t have it? Well, where there is no control or planning, many mistakes are happening.

The quality should be managed from the moment of receiving the raw material, to the final product manufacturing. That is why to ensure that the factory has a well-managed QC system, our auditor will check the IQC (incoming quality control), IPQC (in-process quality control) and FQC (final quality control) records of the factory.

Moreover, the auditor will verify the related equipment that the factory owns for internal quality control – the more advanced QC department the supplier has with various equipment, the better product quality is controlled internally.

6. Research & development

If you are looking for an innovative supplier that strives for improvement and new technology implementation – here is the audit part that you need to pay attention to.

This part is dedicated to check whether the supplier owns any brands or patents, or can design new items and samples. Does the supplier test his pre-production samples internally, and have the ability to assess the various performance of the new item? These are the main questions for this part.

7. Special requirements

Apart from our audit checklist, we also can customize the audit template as per the customer’s needs and perform the tasks that the customer pays most attention to. Here are some of the examples for the SR questions our customers ask us to do during the audits:

Check the product certificates and validity of the certificate

Check warranty certificates of the raw materials

How does the factory research the new suppliers to keep up-to-date with new technologies?

Is the factory facing bankruptcy?

If you are interested in conducting an audit on your potential supplier, feel free to let us know.

Want to learn more about factory audit, please find: 7 Types of Factory Audits that Help to Evaluate Your Supplier

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index