Loading Supervision (LS)

The final but crucial step in the quality control process is properly preparing batches for shipping to destination markets. Loading Supervision (LS) is usually performed at the factory, forwarders warehouse, or port to verify count, confirm load, and seal the container. These inspections also ensure that the products are consistent with the packing list of the client, ensure the correct amount of different styles, sizes, and quantities, and that they are properly loaded to minimize the risk of damage during transit.

What is Loading Supervision (LS)

Loading Supervision (LS) is a service that centers around closely supervising the loading of merchandise or industrial goods into shipping containers. The loading of containers generally conducted at the factory or port to verify count, confirm load and seal container prior to the container being sealed for export. These inspections also ensure that the product has not been tampered with.

The main deliverable of container loading monitoring services is a detailed report of the entire process observed by the auditor: reports will include a detailed account and photos of the loading and transport activities, especially any information related to damage sustained during this process. Clients may also request to be notified immediately of any improper handling of the goods.

What are the benefits of Loading Supervision (LS)?

-Ensure your products are transported in the appropriate conditions.

-Verify the right goods are loaded into the containers (no substitution).

-Guarantee you receive the total order quantity at the destination.

-Confirm your products are packaged and shipped as per conditions stated on the sales contract.

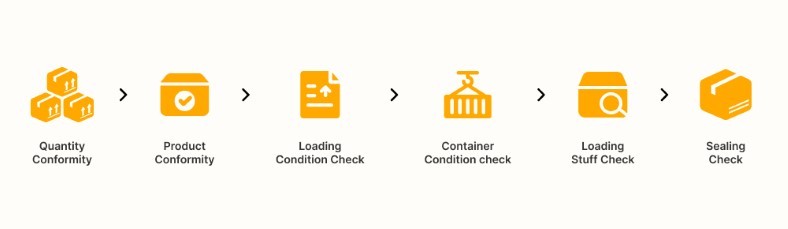

How Loading Supervision (LS) is conducted?

1. Quantity Conformity

Check carton stock in warehouse according to the packing list, if any deviation, record the actual on the report.

Calculate the quantity of each item by order quantity, shipment quantity, packed quantity, packed cartons, and quantity not finished to ensure the accurate number of products were packed into each export carton.

2. Product Conformity

Proper product packaging is critical for an organized supply chain, safety compliance, and brand integrity. Open cartons and check the product package to ensure they meet the agreed specifications at the start of the order. In the event the suppliers fail to include warning labels or incorrect packaging is revealed, this check can allow for the opportunity to correct those mistakes before leaving the factory. This check provides a final opportunity to identify any bad quality products and indicate any critical mistakes that could lead to user injury or company liability.

3. Loading Condition Check

Record the loading time day or night; Weather or any other special condition. Take photo for any special condition.

4. Container Condition check

All container should be free from damage, broken, dirt, wet; the container number should be legible & correct as shown on specification from shipper. Take photo of whole container view & container No. & empty container inside view.

5. Loading Stuff Check

Check and inspect all cartons stuffed, any wet, damaged, broken or defect package should be replaced or repaired accordingly. Take photo for the first row, 1/4 container, 2/4 container, 3/4 container, full container & the overview when close the right door of container. if the container is not completely filled by cartons, ensure the cartons stacking step by step for buffering to avoid falling off when open the container door, if applicable, a protective net seal at the end is preferred.

6. Sealing Check

Check shipper's seal No. against to the specification from shipper, ensure the container door is properly closed and sealed by shipper's seal and other seal if available. Take photos for overview of container closed doors, seals & overview of container before leaving.

Container Loading Supervision is the last opportunity you have to conduct a check for your products and the container will be shipped in. Protect your investment and ensure your cargo will arrive safely at its final destination with a container inspection.

Our Testcoo inspector will produce a full and detailed inspection report, together with a photographic record within 24 hours of the inspection allowing you to see the work undertaken. We have a global network of inspectors and can arrange your inspection within 24 hours of receiving your request.