Acceptable Quality Level (AQL)

What Is Acceptable Quality Level (AQL)?

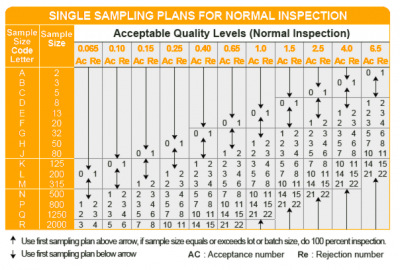

The acceptable quality level (AQL) is a measure applied to products and defined in ISO 2859-1 as the “quality level that is the worst tolerable.” The AQL tells you how many defective components are considered acceptable during random sampling quality inspections. It is usually expressed as a percentage or ratio of the number of defects compared to the total quantity.

KEY TAKEAWAYS

The acceptable quality level (AQL) is the worst quality level that is tolerable for a product.

The AQL differs from product to product. Products that might cause more of a health risk will have a lower AQL.

Batches of products that do not meet the AQL, typically based on a percentage measurement, are rejected when tested during pre-shipment inspections.

How Acceptable Quality Level (AQL) Works

Goods in a sample are tested at random, and if the number of defective items is below the predetermined amount, that product is said to meet the acceptable quality level (AQL). If the acceptable quality level (AQL) is not reached for a particular sampling of goods, manufacturers will review the various parameters in the production process to determine the areas causing the defects.

Important: The AQL of a product can vary from industry to industry; medical products, for example, have stringent AQLs because defective products are a health risk.

As an example, consider an AQL of 1% on a production run. This percentage means that no more than 1% of the batch can be defective. If a production run is composed of 1,000 products, only 10 products can be defective. If 11 products are defective, the entire batch is scrapped. This figure of 11 or more defective products is known as the?rejectable quality level (RQL).

The AQL is an important statistic for companies seeking a?Six Sigma?level of?quality control, which is a quality-control methodology developed in 1986 by Motorola, Inc. AQL is also known as the acceptable quality limit.

Special Considerations

The AQL of a product can vary from?industry to industry. For example, medical products are more likely to have more stringent AQL because defective products can result in health risks.

In contrast, a product with benign side-effects from a possible defect may have a less strict AQL, such as the remote control for a TV. Companies have to weigh the added cost associated with the stringent testing and potentially higher spoilage due to a lower defect acceptance with the?potential cost?of a?product recall.

Customers would, of course, prefer zero-defect products or services; the ideal acceptable quality level. However, sellers and customers usually try to arrive and set acceptable quality limits based on factors typically related to business, financial, and safety concerns.

AQL Defects

Instances of failure to meet customer quality requirements are termed as defects. In practice, there are three categories of defects:

Critical defects:?Defects, when accepted could harm users. Such defects are unacceptable. Critical defects are defined as 0% AQL.

Major defects:?Defects usually not acceptable by the end-users, as they are likely to result in failure. The AQL for major defects is 2.5%.

Minor defects:?Defects not likely to reduce materially the usability of the product for its intended purpose but that differ from specified standards; some end users will still buy such products. The AQL for minor defects is 4%.

AQL in Practice

Acceptable quality level (AQL):?AQL is typically considered to be the worst quality level that is still considered satisfactory.?It is the maximum percent defective that can be considered satisfactory. The probability of accepting an AQL lot should be high. A probability of 0.95 translates to a risk of 0.05.

Rejectable quality level (RQL):?This is considered an unsatisfactory quality level and is sometimes known as?lot tolerance percent defective?(LTPD). The consumer’s risk has been standardized in some tables as 0.1. The probability of accepting an RQL lot is low.

Indifference quality level (IQL):?This quality level is somewhere between AQL and RQL. Different companies maintain different interpretations of each defect type.

However, buyers and sellers agree on an AQL standard that is appropriate to the level of?risk?each party assumes. These standards are used as a reference during a pre-shipment inspection.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index